Within the sturdy confines of our homes, walls play a crucial role beyond mere separation—they provide support, structure, and stability. Among these walls, some bear the weight of the entire building, shouldering the responsibility of maintaining the structural integrity. These are load-bearing walls. The question of whether a wall is load-bearing or not is not just a matter of curiosity; it holds the key to understanding how our homes stand and function. In this load bearing wall removal guide, we will embark on a journey through the realm of interior walls, exploring the signs, and methods that can help you unravel the mystery of whether a wall is carrying more than just its own weight.

Whether you’re planning a renovation or simply seeking to understand the basic structure of your home, join us as we delve into the intricacies of load-bearing walls and empower you with the knowledge to make informed decisions about your interior renovation project.

Identifying Load-Bearing Walls: Key Indicators

Every home is different. So, it can be difficult to know without removing some drywall. Use these methods to know if a wall is load bearing.

- Review Original Plans: The most straight-forward method is to refer to your home’s original drawings. If you don’t have them, contact your local building department to request property records.

- Basement Inspection: If the wall in question aligns with a beam or another wall in the basement, it’s likely load-bearing.

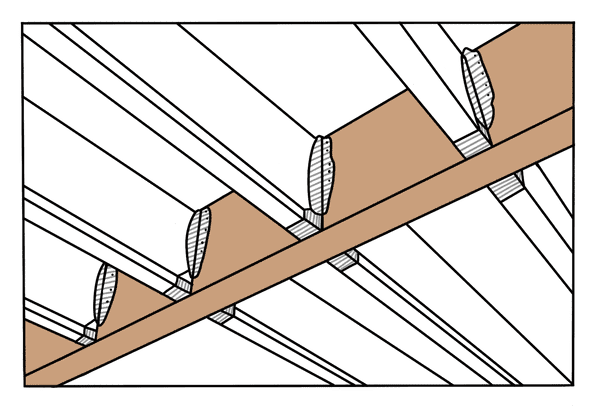

- Attic Assessment: Trusses resting on exterior walls usually indicate non-load-bearing walls. However, if ceiling joists rest on the wall in question, especially if they’re perpendicular, it’s a strong sign of a load-bearing wall.

- Check for Headers: Headers or lintels above doorways, especially if they are 2×10″ or 2×12″, suggest a load-bearing wall.

- Consult an Engineer: When in doubt, consult a professional. At Kingswood Engineers, we can often determine the nature of a wall with clear photos.

Beam Materials: Wall Removal Basics

When removing a load-bearing wall, it’s essential to replace it with a suitable support beam. Our team at Kingswood Engineers Ltd. helps you choose the ideal beam for your specific needs, balancing both the engineering demands and your home’s looks. Here are the most common types:

| Dimensional Lumber: | Cost effective and readily available. The ideal choice when the proposed opening is small. |  |

| LVL: | Layered Veneer Laminate is designed to be as workable as regular lumber, but with a much higher capacity, allowing for longer unsupported spans. Great choice for medium sized openings. |  |

| Steel: | These are the powerhouses of support beams. While not as naturally appealing as wooden beams, they can be painted or boxed in to blend seamlessly with your décor. By Far, the strongest option and ideal when a flush ceiling is required. |  |

Beam Installation Options

There are several installation options available when removing a load bearing wall.

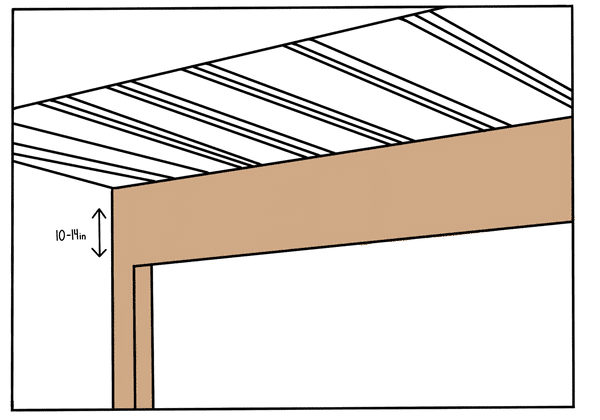

Overlapping Setup

Beam is placed directly underneath the existing ceiling joists. This is the simple stand most common approach but does take 10-14 inches of headroom.

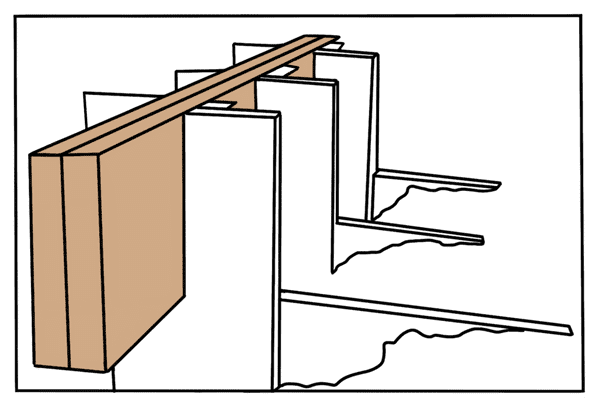

In-line or Flush Setup

The ceiling joists are cut back, and the beam is placed in between the existing joists. Then, the joists are attached to the beam via steel hangers and nails or screws. This option allows for an extra 6-8 inches of headroom in a load bearing wall removal.

Blind Beam Setup

Finally, if there is only an attic space above the wall to be removed, there is an option to install the new beam entirely within the attic and use steel bracket to hold the ceiling joists. This is the least messy option and allows for all the work to be complete prior to the removal of the existing wall below. It also results in a flush beam design.

Examples of Beam Installs

When thinking about a wall removal renovation project, one of the pivotal decisions involves the selection and design of beams. The choice of beam can significantly influence both the aesthetics and use of the renovated space. Cost is a large factor in this decision. A good structural engineer should be able to create a design that minimizes construction costs and maxs the appeal of the reno. Here are some typical installs when removing a load bearing wall and replacing it with a structural beam.

Dropped Beam: The Standard

Dropped beams, typically constructed from dimensional lumber, offer a timeless and easy to install option for homeowners seeking a classic aesthetic when doing a load bearing wall removal. Whether you’re leaning towards a vintage touch or a blend of old and new, dropped beams can quickly fit into various design visions.

| PROS | CONS |

| Simpler Installation: Dropped beams are often easier and quicker to install since they don’t require integration within existing ceiling joists. Cost-Effective: Typically, this method can be less expensive due to the reduced labour and modifications needed. Design Opportunities: The visible beam can be used as a design feature, allowing for embellishments like coffered ceilings or decorative mouldings. |

Reduced Ceiling Height: The beam sits below the ceiling line, which can make the room feel shorter and less open. Potential Aesthetic Disruption: If not integrated well into the room’s design, it can stand out and disrupt the visual flow of the space. |

Flush Beam Installation: Modern Engineering Meets Design

LVL (Laminated Veneer Lumber) flush beams integrate seamlessly with the ceiling. Overall, they promise robust support without overshadowing the room’s visual appeal. Finally, LVL beams bolster the expansive feel of interiors, making them an ideal choice for those seeking a blend of strength and style.

| PROS | CONS |

| Seamless Aesthetics: The beam is integrated within the ceiling, offering a clean and uninterrupted ceiling line. Maximized Ceiling Height: This method retains the original ceiling height, making rooms feel more spacious. Versatility: Suitable for both modern and traditional interiors due to its inconspicuous nature. |

Complex Installation: Requires careful alignment with existing joists and potentially more structural adjustments. Potential Additional Costs: Might necessitate modifications to existing HVAC or electrical systems, leading to increased renovation expenses. |

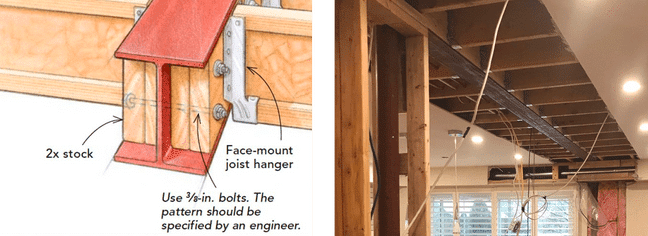

Packed Steel I-Beam: The Strongest Option for a Load Bearing Wall Removal

LVL (Laminated Veneer Lumber) flush beams in load bearing wall removals fit seamlessly with the ceiling. They promise robust support without overshadowing the room’s visual appeal. Overall, such beams bolster the expansive feel of interiors. Therefore, this makes them an ideal choice for those seeking a blend of strength and style.

| PROS | CONS |

| High Strength: Steel I-beams provide superior load-bearing capacity, making them ideal for larger spans or areas with significant structural demands. Flush Design: Steel is typically the only option to get a flush design when there are bedroom about the proposed opening. Lumber is too large to fit inside the joist cavity. |

Cost: Labour and material costs are the largest drawback to making this the default option. For larger spans it is often the only viable option. Weight: Steel beams are considerably heavier than wooden counterparts, which might require additional supports or reinforcements during installation. Additionally, a typical beam will approach 600-900 lbs, requiring the use of hoists to install. Contractor Skill: There are many contractors in Ontario that are not comfortable working with steel and prefer to work with LVLs or dimensional lumber. Getting quotes specifically from structural contractors is a good idea. |

The Construction Process

Time needed: 4 days and 12 hours

The most important step to take is to hire a contractor with experience. For structural work on your home, you want peace of mind. The main steps are:

- Safety and Design

Even before the installation begins, it’s crucial to ensure that designs allow contractors to put up temporary supports for safety during the reno process.

- Beam Sizing and Design

Collaborate closely with experts to determine the optimal beam design based on structural requirements and aesthetic choices.

- Flush Beam Considerations

Overall, designs should provide guidance on the cost of flush beams, considering factors like HVAC/electrical changes and the overall look of the renovated space.

- Understanding Load Transference

It is important that the beams have enough support in a load bearing wall removal. The posts need to transfer the loads effectively to the foundation.

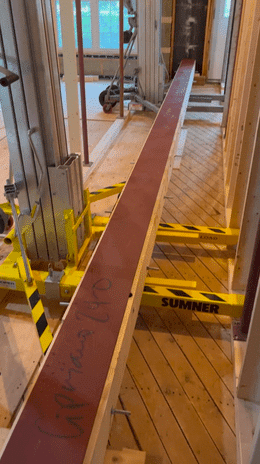

Installation Example – Packed Steel I-beam

Wall removal renos can change a space, creating a sense of flow. However, understanding the technical aspects, like beam design, is crucial for a successful project. Be informed and work with experts. This ensures the reno aligns with both structural needs and design goals.

Steps involved in this Wall Removal renovation in Hamilton, by the team at Cipriano Construction Inc:

- Demolition finished, only stud framing remains.

- Temporary supports installed, the old load bearing wall is removed.

- Floor joists cut back to make space for the new packed beam.

- New steel I-beam is packed with lumber to allow for easy joist hanger installation.

- New steel posts are welded to the new steel I-beam.

Steel Beam Installation in Oakville

One of the most critical and fascinating aspects of replacing a load-bearing wall is the installation of a steel beam. This process is not only a testament to engineering ingenuity but also a crucial element in ensuring the structural integrity of your home. We’ve captured a captivating moment where a steel beam is expertly hoisted and positioned into place – a procedure that epitomizes the precision and skill involved in our work.

Witness this remarkable process in the video below, and discover the seamless blend of strength and design that goes into each of our projects. The installation was expertly carried out by G&G Home Design, renowned for their meticulous attention to detail and structural expertise. To learn more about their incredible work, visit G&G Home Design.

Load Bearing Wall Removal Timelines: What to Expect

When considering a interior reno, especially those involving structural changes, home owners often wonder about the time and costs involved. This guide aims to shed light on the typical timeline and costs of a beam installation and load-bearing wall removal.

| Phase | Duration | What is Involved |

| Engineering Design | Typically spans 5-12 business days after initial measurements. | Creation of a detailed plan for beam installation, ensuring structural integrity and alignment with vision. |

| Building Permit Approval | Officially 10 business days, but can vary between 3 to 8 weeks due to high demand in Ontario. | Ensuring all planned activities comply with local building codes and regulations. |

| Construction | Actual removal and installation takes 4-7 days. Contractor availability can vary, with most being available within a 1-3 week timeframe. | Physical removal of the wall, installation of the beam, and necessary adjustments. |

Project Costs: What to Expect

Structural Wall Removal & Beam Installation: Estimated at $250 – 350 per linear foot.

New Footing (if required): Starting from $2700.

Clients ask us how much does it cost to do a load bearing wall removal? The short answer is: $3K for permit, $5-7K per beam for constructor, and finishing costs are the same as a regular reno. Additionally, it is very important to clearly understand the what the quote does not include. Take your time at this stage as you do not want to get into a cost spiral halfway through your reno.

| INCLUDED | NOT INCLUDED |

| Demolition and disposal Installation of temporary support structure during the removal Reframing and installation of the new beam and hangers if a flush mount is selected |

The cost of the beam itself The removal and rerouting of electrical wiring, HVAC ducts, and plumbing (if necessary) The installation and finishing of drywall Priming and painting to match your existing décor |

How Much Does a Load Bearing Wall Removal Project Cost?

Removing a load-bearing wall is more involved than taking down a non load-bearing wall. The construction costs for removing a load-bearing wall in a single-story home can range from $4,000 – $5,500. If the project includes rerouting utilities, costs can rise to $6,000 – $10,000. In addition, for second story load-bearing walls, which may require additional support or the use of a steel I-beam, costs can range from $8,000 – $12,000.

Remember, while this blog provides general information. Overall, consult with professionals on the specifics of your home and region for precise estimates and advice.

Flush Steel I-Beam Installation in Mississauga

In a recent project in Mississauga, Ontario, a noteworthy example of this type of residential renovation is observed. The installation of two flush steel I-beams, designed by Kingswood Engineers Ltd. and installed by G&G Home Design, exemplifies the technical intricacies involved in modern wall removal and structural reinforcement.

The video highlights the steel beams being precisely positioned on the exterior foundation walls, a critical step for maintaining structural integrity. Additionally, the attachment of wood joists to the steel beams using hangers illustrates a seamless integration of materials, combining stability with aesthetic appeal.

Get Started

As your engineering partner, Kingswood Engineers Ltd. strives to provide you with as much information as possible to help you plan and budget your project accurately. With our technical expertise and strong connections with reliable contractors, we ensure that your wall removal project is a success, every step of the way.